With the Capability to go up to Nine Storeys

With technical expertise to deliver light steel solutions for multistorey buildings, our loadbearing structures are designed to relevant Building Regulations and Building Safety Standards, to create full structures to which facades are then applied. Light steel frames and components are combined to form external, separating and internal walls together with roof structures.

Providing comprehensive design and full structural calculations, our light steel frame loadbearing solutions are becoming the first choice for the construction industry. Exploiting offsite manufacturing techniques, we are able to produce precision engineered loadbearing systems with the capability to go up to nine storeys. Early engagement with Frameclad’s design and engineering team maximises the benefits of our loadbearing solutions.

Loadbearing Benefits in Brief

Frameclad can provide loadbearing systems to suit most type of applications from individual houses to commercial multi-storey developments. Due to the lightweight structure, this system can lend itself to building a new storey or storeys on existing buildings subject to structural engineering approval. The true benefits lie in the advantages that early engagement can bring – the invisible cost savings that lighter construction can deliver such as:

Reducing Foundation Requirements – as our loadbearing systems decrease the overall building weight, a similar reduction in the cost and carbon impact of the foundations can be achieved. Reducing the weight of the super-structure is particularly advantageous on inner city development sites with poor ground conditions or constructing roof top extensions on existing buildings.

Better Return on Investment – manufacturing lighter structures can result in additional storeys on inner city developments where underground infrastructures reduce loading requirements.

Time and Cost Savings – our advanced offsite construction technology achieves accelerated building programmes which offer both time and cost savings – delivering a faster return on investment.

Factory Precision – by achieving greater dimensional accuracy, we deliver robust structures built to exacting requirements that are highly airtight and energy efficient which reduce heating costs and carbon emissions for the lifetime of the building.

Solutions

Have A Question? Get in Touch

Frameclad's Pre Boarded Floor

Reduced Installation Time

Our pre boarded floor option is an excellent example of the kind of solution which enables our clients to work with maximum efficiency and build at speed without sacrificing anything in terms of quality. This floor solutions from Frameclad offers an innovative load bearing construction solution which can be installed to extremely tight lead in times while allowing architects and builders to add height to existing buildings.

Eliminate Scaffolding and Reduce Downtime with Pre boarded Floors

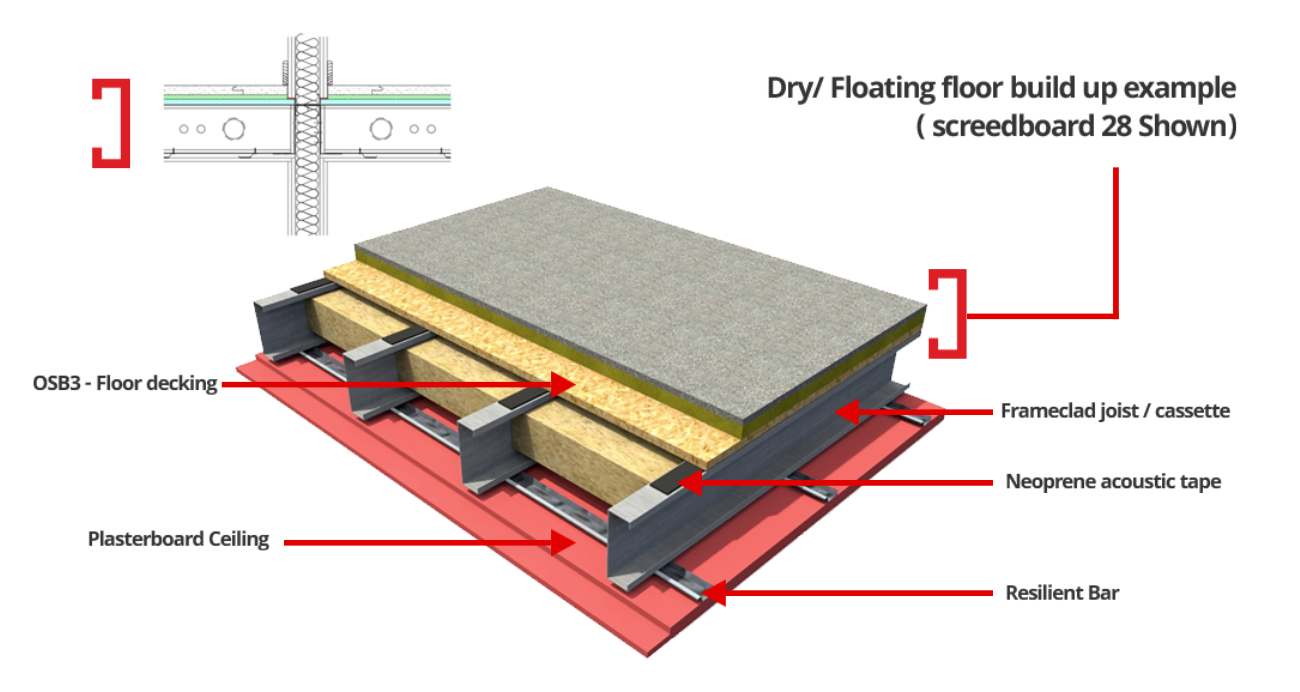

Our pre-boarded floor cassette systems provide several benefits, including versatility, consistency, shear strength and sustainability. There are several options for the floor finish and build up but all have excellent credentials and benefits.

The advantages of all of our pre-boarded floor cassette solutions begins with the fact that it can be built into a structure without scaffolding having to be put up, thanks to its compatibility with our edge protection system. This edge protection system means that the cassettes once manoeuvred into place on site and fixed form a true working platform with no necessity for scaffolding. This is typical of the kind of time-saving convenience which our pre-boarded floor cassette systems offer from start to finish, with all dry construction methods meaning that there is never a requirement for the build to come to a standstill while concrete is poured and allowed to dry.

The make-up of the deck floor itself consists of multiple layers built around the steel Frameclad joists, each layer offering greater strength and resilience without adding excessive weight, and layers such as the screedboard and neoprene acoustic tape making this the ideal solution for both domestic and commercial locations.

Reduce Your Carbon Footprint with A Pre-Boarded Floor Cassette Systems

In addition to improving a finished building, the pre-boarded floor cassette systems can be utilised as a working platform, and our ability to work to precise and consistent specifications means that we can create sections of deck floor in bulk and deliver on mass to reduce the number of visits to the construction site.

Our pre-boarded floor cassette solutions can play a key role in reducing the overall carbon footprint of a building, conforming to legislation and enhancing the corporate branding and eco-credibility of any client working with Frameclad.

Pre-Boarded Floor Cassette Systems Offer an Innovative Alternative to Traditional Methods

The pre-boarded floor cassette system is lightweight yet robust, easy to install, versatile, eco-friendly and functional. It offers an innovative alternative to traditional solutions which, in simple terms, makes it easier for designers, architects and builders to take ideas from the drawing board to the real world.

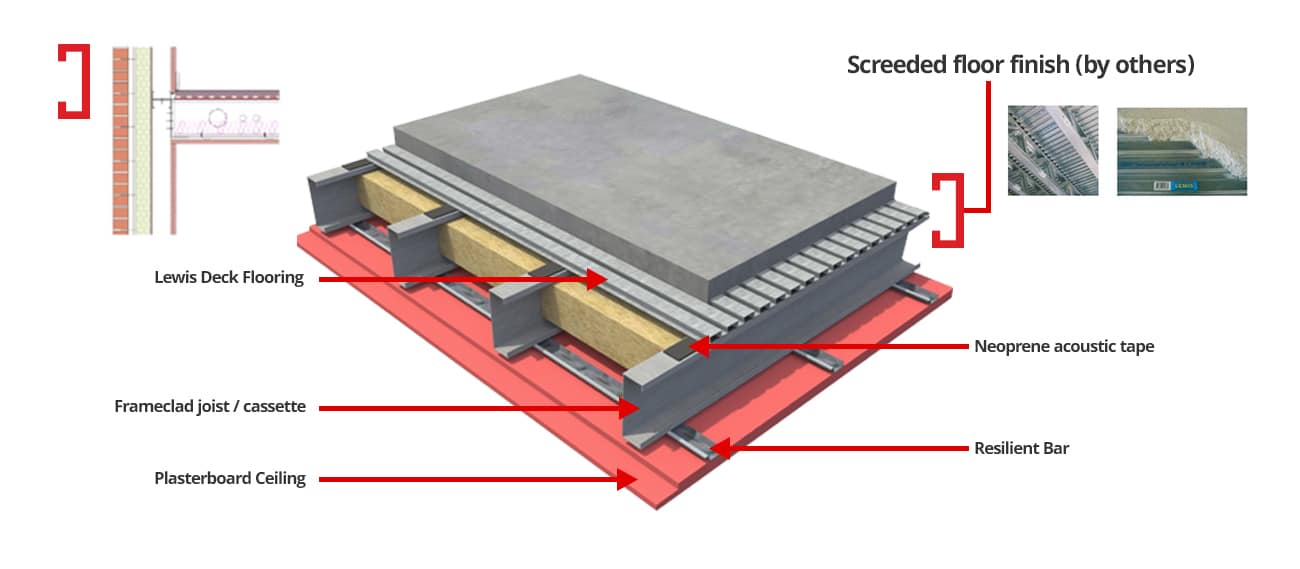

Frameclad's Lewis Deck Floor

Lewis Deck Floor offers a solution which is typical of the kind of options that Frameclad specialise in. It enables anyone using it as part of their project to install load bearing flooring at speed without compromising on the quality of the finished product. It provides the ideal solution for builders, designers and architects working to tight lead times, enabling them to add height to buildings quickly and safely.

Eliminate The Need for Scaffolding

The lightweight nature of the Lewis Deck floor option is that it offers numerous advantages, not least of which is the fact that it’s easier to work with and can be transported quickly to site and lifted into position as part of a floor cassette system. Once in place, the deck floor sections are compatible with SFS edge protection systems which means that the work of installing them can take place without scaffolding. This reduces the costs of a project, saves time-on-site and frees up members of the team who would otherwise be engaged in putting the scaffolding together or waiting for it to be in place.

Reduce The Number of Visits to Site with Our Lewis Deck Floor

Lewis Deck floor offers an enhanced alternative to concrete flooring as it offers the same versatility, shear strength and longevity without work having to be halted while the concrete itself is poured and left to cure. On the contrary, the deck floor units offer the ‘feel’ of concrete without any of the inconvenience, and the finished installation is lighter than concrete flooring and can therefore be supported by a wider range of structures. The fact that the deck itself can act as a working platform means that a project can be delivered at speed with maximum safety, and the fact that sections of the deck floor can be manufactured in bulk to precise and consistent specifications cuts the number of deliveries made to the site. This is one reason why using the Lewis Deck floor option helps to cut your projects carbon footprint, enabling projects to be delivered in line with legislation and with an eco-friendly stance that enhances corporate branding and meets the demands of increasing numbers of modern clients.

An Eco-Friendly Alternative

Lewis Deck floor is versatile, eco-friendly and robust. It offers a lightweight alternative to traditional building methods and is an innovative choice for designers, architects and builders. It is quick and easy to install and keeps projects moving forward quickly while delivering high-quality results.

What is Loadbearing?

Understanding loadbearing is crucial when undertaking any construction project. Loadbearing walls provide the structural integrity of a building and ensure that it’s safe. In every building, the walls are divided into internal and external, and some of those walls will be loadbearing while others are non-loadbearing. Knowing which walls are loadbearing will keep construction projects safe and help you manage costs. So how can you tell if walls are loadbearing? Walls are load bearing if they carry the weight of the building. The load is transmitted through walls to foundation columns or beams through studs, floor joists, and rafters.

The Different Types of Loadbearing

Loadbearing walls come in many different forms. Loadbearing walls you commonly find in buildings include retaining walls, which are used to provide lateral support, masonry walls to provide strength and durability, and metal stud walls which are used to construct exterior wall cladding.

Materials Used in Loadbearing

The loadbearing walls are usually either made out of concrete, light gauge steel framing, or wood studs. In commercial buildings, loadbearing walls tend to be constructed with steel.

The Benefits of Building Loadbearing Walls with Light Gauge Steel

Durability

Loadbearing walls constructed with light gauge steel framing do not deteriorate over time. Other types of loadbearing walls such as timber frame have the potential to rot when exposed to moisture. Less maintenance is required with loadbearing walls made of light steel frame because they withstand the elements as the components being used are galvanised.

Lightweight

Loadbearing walls made of steel are much lighter than loadbearing walls built using concrete or wood studs, making them easier to install and maintain.

Flexible Design

Because loadbearing walls made of steel are lightweight and durable, they can be tailored to each construction project. Light gauge steel frames can be custom-made to your specifications, allowing them to be used in a wide range of projects.

Speed of Construction

The loadbearing walls made of steel framing can be installed quickly, a benefit that makes loadbearing construction projects more affordable. Steel load bearing walls can also be assembled using a crane, making load bearing walls easy to install even if they are in an awkward or hard to reach location.

Eco-friendly Solution

The loadbearing walls made of light gauge steel framing are eco-friendly and carbon neutral. They can last for one hundred years or more without deteriorating, so they don't require replacement like loadbearing walls made of concrete or wood. These loadbearing walls are sustainable and do not harm the environment.

Don’t Wait; Enquire Today

Don’t wait; take the next step and enquire about Frameclad’s light gauge steel loadbearing today via our quick and easy contact form below. Alternatively, you can get in touch with a member of our team today on 01384 401 114 or by emailing us at enquiries@frameclad.com. We look forward to hearing from you. We look forward to hearing from you.

Have A Question? Get in Touch

Case Studies

Windsor House

In the heart of contemporary Sutton, surrounded by immense culture and diversity, we are delighted to introduce striking new apartments providing the brightest and lightest homes available on a Shared Ownership Scheme. Windsor House is the newest development undertaken by Optivo, giving potential residents the opportunity to live in the desirable and sought after Borough of Sutton.

Think On Top Of The Box

Located in a coastal location, this was a conversion of an existing 3 storey concrete frame building into 9 townhouses. Frameclad provided the SFS infill to form new external walls to the existing levels then added a self-supporting top floor with SFS to give additional floor space to the scheme. Due to the restrictive nature of the site and the need to keep the new loadings of the upper floor to a minimum, SFS was the ideal solution for the developer.