Meeting the Future Homes Standard

With a 12-strong in-house team of designers and engineers, Frameclad are gearing up to meet the demands of the Future Homes Standard which comes into force next year. The more stringent regulations should ensure that all new homes will produce 75-80% less carbon emissions than houses delivered under current regulations.

Increasing Thermal Efficiency - In addition to being strong, sustainable and cost efficient, light steel frames also provide excellent thermal insulation properties. Effective airtightness measures in light steel frame construction include using membranes or sheathing materials to create a continuous air barrier and accurate detailing at interfaces between different building elements.

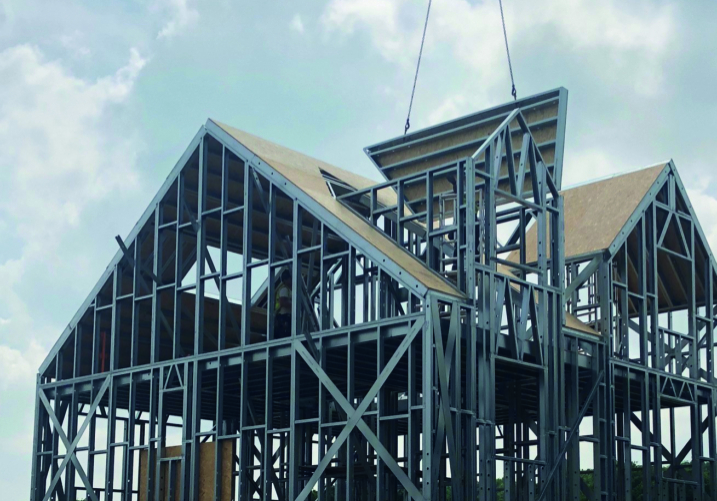

The use of light steel allows for more efficient insulation systems when compared to other materials such as concrete or masonry blocks. The accuracy achieved through the precise manufacturing and assembly of Frameclad’s light steel frame structures delivers high levels of airtightness. Lightweight metal studs create air pockets that can be filled with insulating materials which helps reduce heat loss through walls or roofs and increases thermal efficiency within a structure’s envelope.

Incorporating thermal mass is vital in meeting the Future Homes Standard. With light steel structures this can be achieved by integrating concrete floors, gypsum boards, or using phase change materials (PCMs) within the building envelope. Phase change materials offer a versatile solution for improving thermal performance and energy efficiency in buildings and can help to stabilise indoor temperatures and reduce heating and cooling loads. Placing windows strategically on the south side of a building allows for greater solar heat gain during the winter months. When designing window positions in light steel frame construction, it is essential to consider both thermal performance and airtightness goals.

Overall, light steel provides many environmental benefits. Its low weight reduces concrete foundation requirements and facilitates easy transport and quick assembly on site. Its ability to support multiple types of finishes make it suitable for a variety of design options allowing architects greater scope in their designs without compromising sustainability goals. In addition, its excellent thermal properties offer significant potential savings in terms of heating and cooling costs throughout the lifespan of any building constructed using Frameclad’s light steel framing systems.

About

As a leading BOPAS design at full scope accredited manufacturer and ISO certified, Frameclad are committed to achieving the highest quality standards, manufacturing all products in an advanced 50,000sqft framing facility, fully compliant with EN 1090- 1: 2009 + AL: 2011 CE accreditation. Through customised Tekla software, the skilled design and engineering team at Frameclad are ensuring construction clients can achieve fully compliant structures, tested in a digital environment.

Read full article in LSF Magazine